Introduction

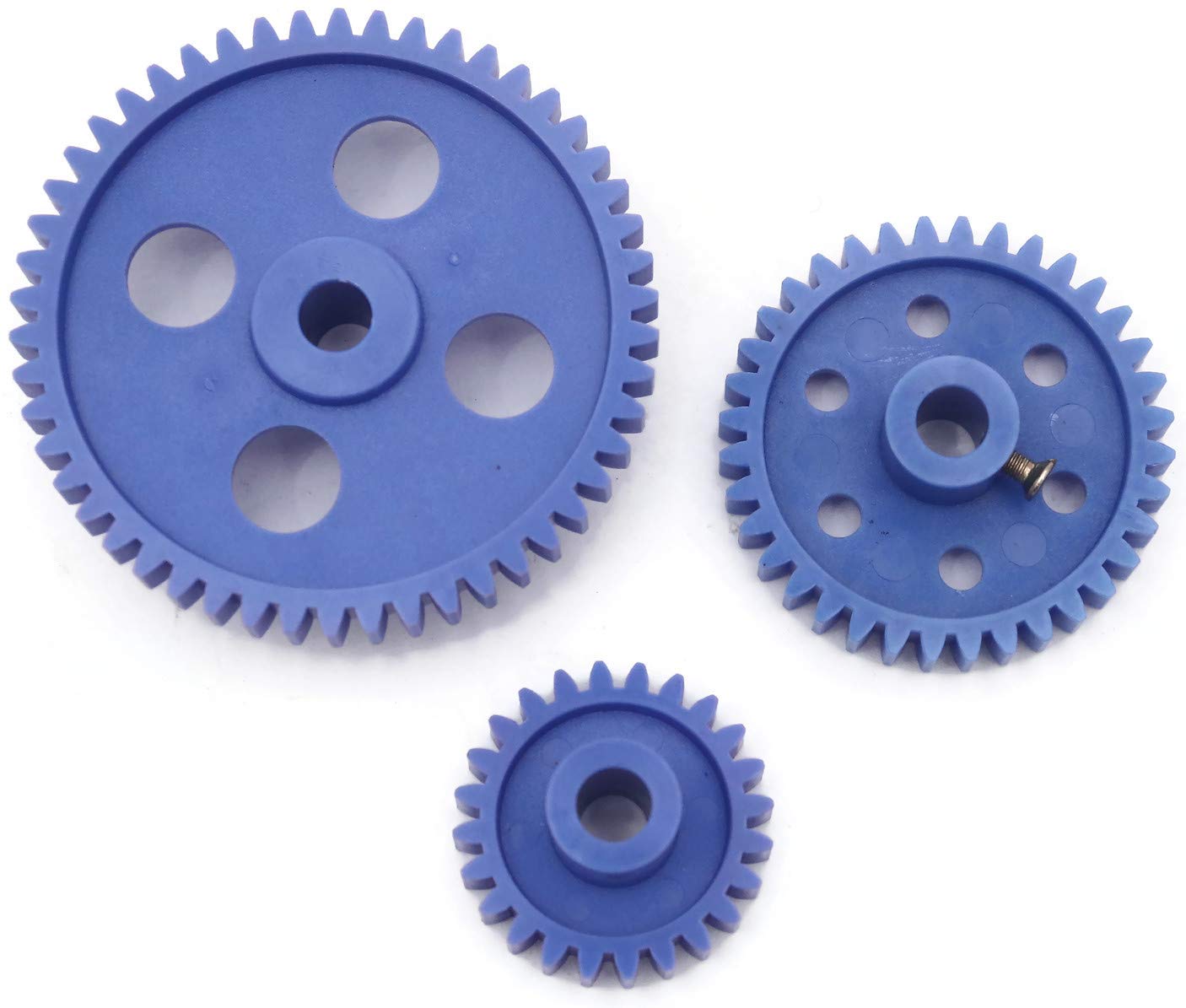

Plastic Gear for Cruise Ship Stabilizers is a crucial component that ensures smooth sailing and stability for cruise ships. This product is specifically designed to withstand the rigorous conditions at sea and provide reliable performance.

Key Points

- Durable Material: The plastic gear is made from high-quality materials that are durable and long-lasting, ensuring reliability in challenging maritime environments.

- Precision Engineering: Each gear is meticulously engineered to ensure smooth operation and optimal performance for cruise ship stabilizers.

- Corrosion Resistance: The plastic gear is resistant to corrosion, making it ideal for use in saltwater conditions without compromising performance.

- Low Maintenance: With minimal maintenance requirements, the plastic gear offers cost-effective solutions for cruise ship operators.

- Efficient Operation: The gear’s design promotes efficient power transmission and ensures smooth operation of cruise ship stabilizers.

Features

- High-quality plastic material

- Precision engineering for optimal performance

- Corrosion-resistant properties

- Low maintenance requirements

- Efficient power transmission

Application

- Marine Industry: The plastic gear is ideal for cruise ship stabilizers due to its corrosion-resistant properties, ensuring reliable performance at sea.

- Water Sports Equipment: The gear’s durability and efficiency make it suitable for water sports equipment that requires smooth operation.

- Automotive Industry: The plastic gear can be used in automotive applications where precision and durability are essential.

- Industrial Machinery: Its efficient power transmission makes it suitable for various industrial machinery applications.

- Aerospace Industry: The gear’s lightweight design and durability make it a viable option for aerospace applications.

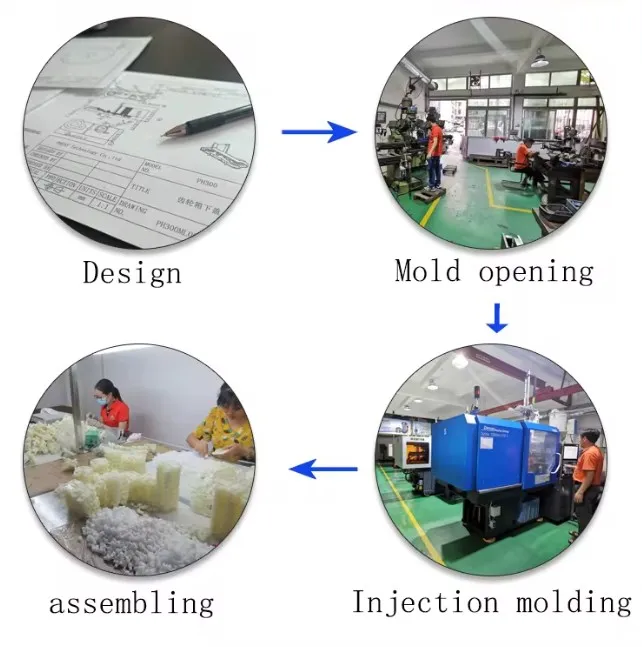

Methods of Manufacturing Plastic Gears

There are several methods for manufacturing plastic gears, including injection molding, extrusion, and machining. Each method has its advantages and is chosen based on the specific requirements of the gear.

Choosing the Right Plastic Gear

- Consider the application requirements, such as load capacity and operating conditions.

- Choose a material that is compatible with the environment where the gear will be used.

- Ensure the gear’s design and specifications align with the machinery it will be used in.

- Check for certifications and quality standards to guarantee performance and reliability.

- Consult with experts or manufacturers to determine the best plastic gear for your specific needs.

Tips in using the plastic gear

- Regularly inspect the gear for signs of wear and tear.

- Follow the manufacturer’s guidelines for maintenance and lubrication.

- Avoid overloading the gear beyond its capacity to prevent damage.

- Store the gear in a dry and cool environment when not in use to prolong its lifespan.

- Replace the gear if any abnormalities or performance issues are detected during operation.

Lubrication of plastic gears

- Use lubricants specifically designed for plastic gears to ensure smooth operation.

- Apply the lubricant sparingly to prevent build-up and ensure proper functioning.

- Regularly clean the gears before applying lubricant to remove any debris or contaminants.

- Follow the manufacturer’s recommendations for lubrication intervals to maintain optimal performance.

- Monitor the gear’s performance after lubrication to ensure smooth operation.

About HZPT

HZPT is a leading manufacturer of plastic gears and other high-performance engineering products. With a team of experienced professionals and innovative technology, we specialize in developing and producing a wide range of plastic and rubber products. Our advanced manufacturing facilities and commitment to quality have earned us a reputation for excellence in the global market. We strive to provide world-class products that meet and exceed customer expectations. HZPT is dedicated to quality, innovation, and customer satisfaction.