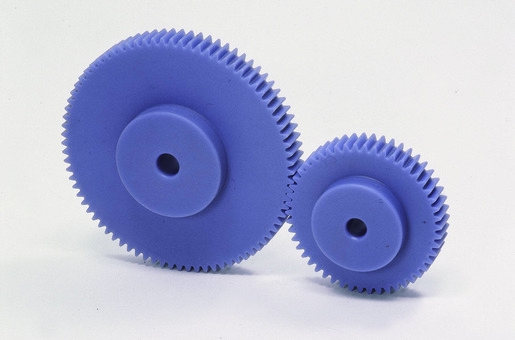

Introduction to Plastic Gear for Massage Chairs

Key Points:

- High-quality plastic material

- Precision engineering

- Quiet operation

- Long-lasting durability

- Smooth performance

Product Features:

- Designed to withstand constant use in massage chairs

- Resistant to wear and tear

- Low maintenance requirements

- Efficient power transmission

- Compatible with various massage chair models

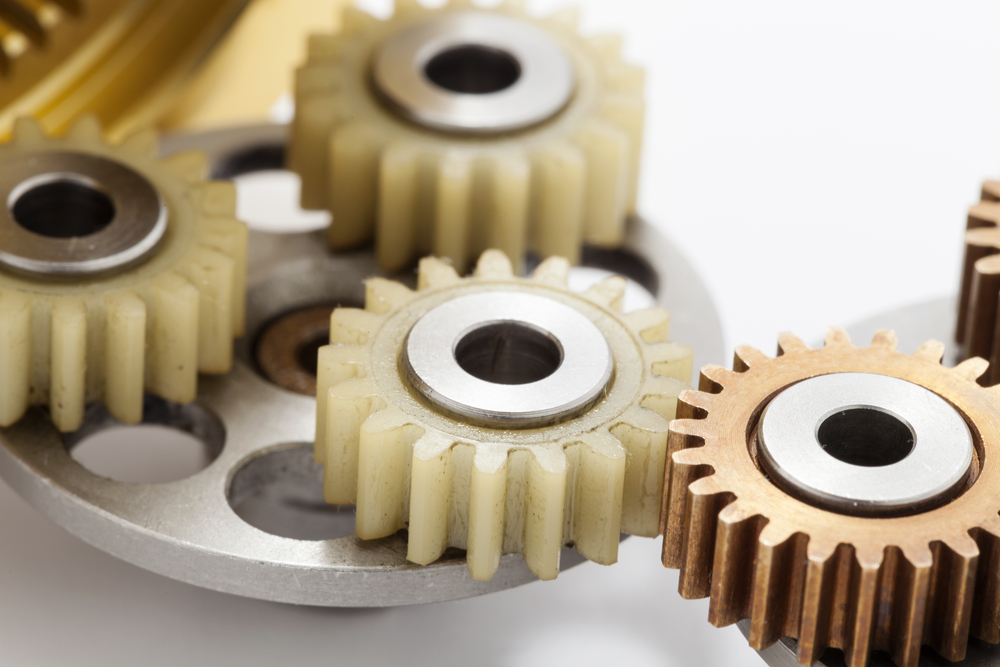

Application of Plastic Gear for Massage Chairs:

- Quiet operation ensures a relaxing massage experience

- Durable material prolongs the lifespan of the massage chair

- Smooth performance enhances the overall massage quality

- Low maintenance requirements reduce downtime

- Precision engineering ensures optimal power transmission

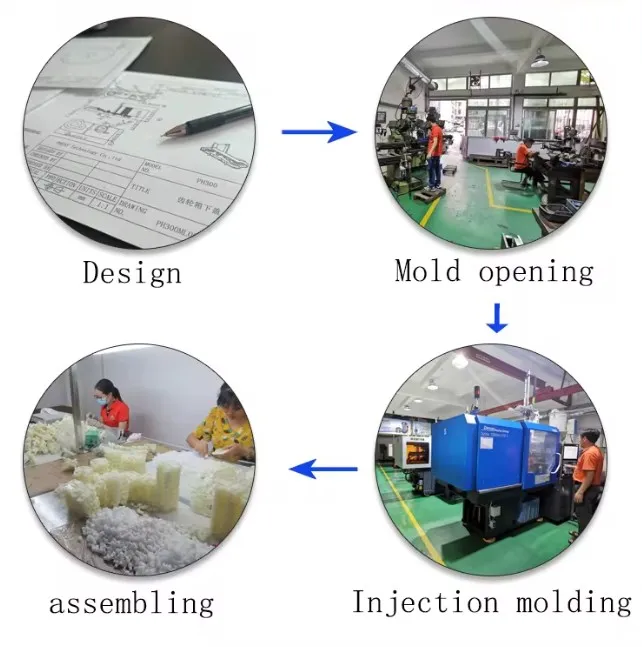

Methods of Manufacturing Plastic Gears:

- Injection molding

- CNC machining

- Extrusion molding

- 3D printing

- Powder metallurgy

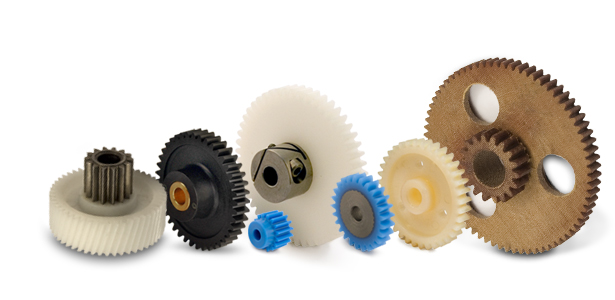

Choosing the Right Plastic Gear:

- Consider the load capacity

- Ensure compatibility with the massage chair mechanism

- Check for noise reduction features

- Look for high-quality plastic material

- Verify precision engineering for smooth operation

Tips in using the plastic gear:

- Regularly clean and lubricate the gear

- Avoid overloading the gear mechanism

- Inspect for wear and tear periodically

- Follow manufacturer’s maintenance guidelines

- Seek professional assistance for complex repairs

Lubrication of Plastic Gears:

- Use compatible lubricants specified by the manufacturer

- Apply lubricant evenly across all gear teeth

- Regularly check and reapply lubricant as needed

- Avoid using excessive amounts of lubricant

- Follow recommended lubrication intervals for optimal performance

About HZPT

HZPT is a leading manufacturer of high-performance plastic gears for various applications, including massage chairs. Our company boasts a team of experienced professionals dedicated to innovation and quality. We specialize in producing a wide range of engineering plastic products, such as nylon, HDPE, UHWMPE, POM, ABS, PEEK, and more. With state-of-the-art production facilities and a commitment to excellence, we ensure that our products meet international standards and customer expectations. HZPT has earned a reputation for providing top-quality products, excellent service, and competitive prices in the global market. Our ISO 9001:2015 certification reflects our dedication to quality and customer satisfaction. Join us in experiencing the reliability and performance of HZPT plastic gears.