Introduction to Plastic Gear Making Machine

Key Points:

- High Efficiency Production

- Precision Engineering

- Durable Material

- Wide Range of Applications

- Cost-effective Solution

Features of Plastic Gear Making Machine:

- Advanced CNC technology for precise gear cutting

- High-quality plastic material for enhanced durability

- Customizable design options for various applications

- Energy-efficient operation for cost savings

- Low maintenance requirements for long-term use

Applications of Plastic Gear Making Machine:

- Automotive Industry: Plastic gears provide lightweight and corrosion-resistant solutions for automotive components.

- Medical Equipment: Precise plastic gears are used in medical devices for accurate performance.

- Consumer Electronics: Plastic gears offer quiet operation and smooth functionality in electronic devices.

- Industrial Machinery: Plastic gears are suitable for various industrial applications due to their durability and efficiency.

- Robotics: Plastic gears are used in robotics for their lightweight nature and high precision.

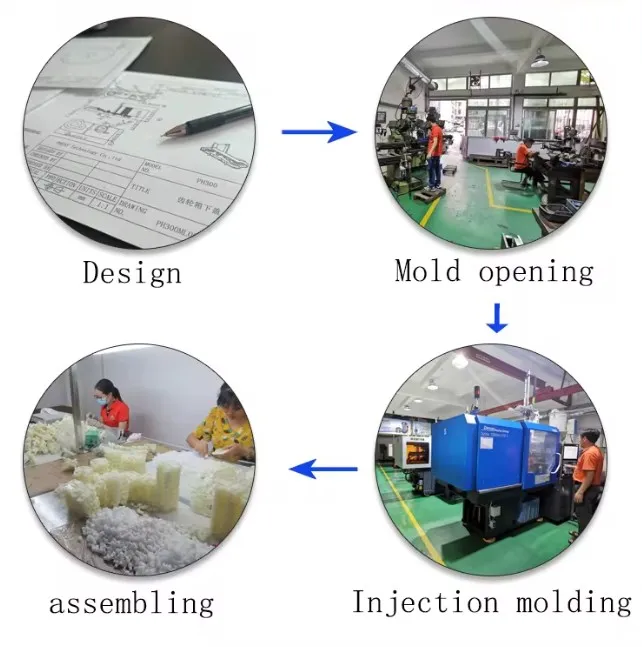

Methods of Manufacturing Plastic Gears:

- Injection Molding

- CNC Machining

- Extrusion

- Powder Metallurgy

- Gear Hobbing

Choosing the Right Plastic Gear:

- Consider the application requirements such as load capacity and operating conditions.

- Choose the appropriate material based on factors like temperature resistance and chemical compatibility.

- Ensure proper gear design for optimal performance and efficiency.

- Evaluate the cost-effectiveness of the gear for long-term use.

- Select a reliable manufacturer with a track record of quality and innovation.

Tips in using the plastic gear:

- Regularly inspect the gear for signs of wear and tear.

- Ensure proper lubrication to maintain smooth operation.

- Avoid overloading the gear beyond its capacity.

- Follow recommended maintenance schedules for prolonged gear life.

- Consult with experts for any troubleshooting or technical assistance.

Lubrication of Plastic Gears:

- Use lubricants specifically designed for plastic gears to prevent material damage.

- Apply lubrication evenly and regularly to reduce friction and wear.

- Monitor lubricant levels and replenish as needed to maintain optimal operation.

- Follow manufacturer recommendations for lubrication frequency and type.

- Keep gears clean and free from debris to enhance lubrication effectiveness.

About HZPT

HZPT is a leading manufacturer of high-performance engineering plastic products, including plastic gears. Our company is dedicated to providing top-quality products and innovative solutions for various industries. With a focus on customer satisfaction and quality excellence, we have earned a reputation for reliability and competitiveness in the global market. Our state-of-the-art production facilities and experienced R&D team ensure that we deliver world-class products that meet international standards.